Nkọwa zuru ezu nke usoro usoro nke usoro ọ bụla nke TOPCON

Ederede

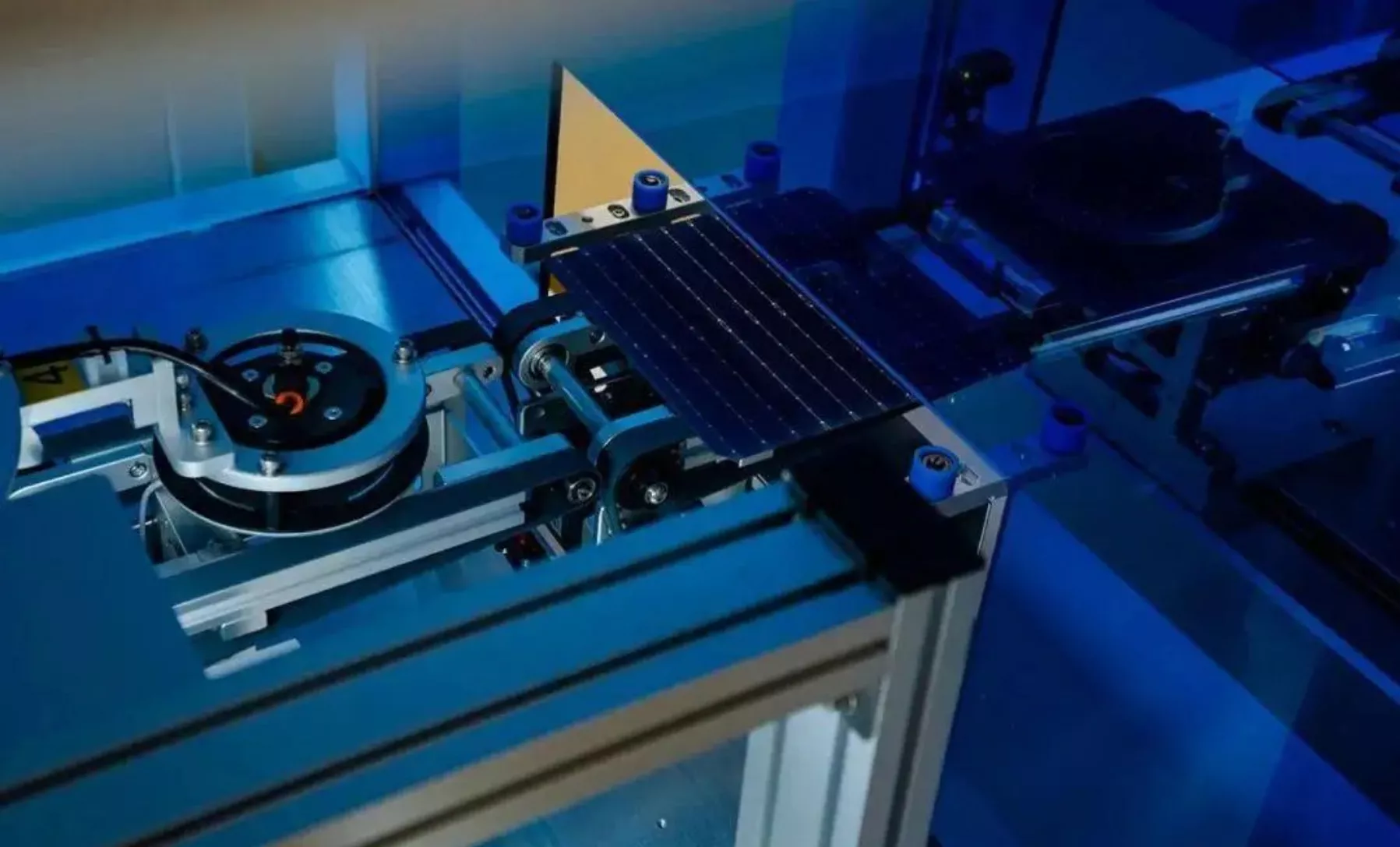

The texturing ngalaba (ngụkọta nke 6 ahịrị) na-agụnye tupu ihicha - mmiri dị ọcha ịsacha tupu texturing - texturing * 3 - dị ọcha mmiri ịsacha mgbe texturing - post-ihicha dị ọcha mmiri ịsacha - pickling - mmiri dị ọcha ịsacha mgbe pickling - ngwa ngwa ebuli tupu. akpịrị ịkpọ nkụ - ihicha * 5 na modul ndị ọzọ. Usoro ederede nke ọrụ a niile na-agbaso ederede akpaka, a na-eme usoro ọrụ niile na-akpaghị aka, a ga-eziga ogwe aka na-ebufe n'ebe a na-eri nri nke igwe texturing mgbe emechara tupu ihicha, silicon wafer na akpaaka mechiri emechi texturing igwe site na roller site ọ bụla corrosion, ihicha tank, akụrụngwa akpaka akara iji gbakwunye acid, lye na mmiri dị ọcha na nke ọ bụla modul, na acid na lye na tank na-pumped na site na pipeline, na mgbe nile (otu tank olu nke 720L, 48h ka. dochie otu ugboro) igbapu mmiri mkpofu na tank.

1) Tupu ihicha

Nzube ihicha tupu: Wepụ ihe ndị na-adịghị mma (ihe ndị na-emepụta ihe, ihe ndị na-emepụta ígwè, wdg) na-arapara na elu nke silicon wafer, na-eji ngwọta NaOH na ngwọta H2O2.

A na-emikpu wafer silicon ndị a na-ebu ibu n'ime tankị a na-ehicha ihe n'aka nke ya, a na-agbakwunye mmiri dị ọcha na tank ahụ, a na-agbakwunyekwa ihe ngwọta NaOH kwesịrị ekwesị ma ọ bụ ngwọta dị ọcha dị ka nha (a na-atụ anya na ịta NaOH ga-abụ 0.6% mgbe agwakọtachara). , A na-atụ anya itinye uche H2O2 ka ọ bụrụ 1.5%, mgbakwunye akpaka) maka nhicha dị elu (60 Celsius C). Tupu ihicha na-eji ultrasonic ihicha. Mmiri dị ọcha ihichachaa tupu emechaa. Nhicha mmiri dị ọcha bụ ihicha imiri mmiri na-ejupụta, a na-eme ya na okpomọkụ ụlọ.

Mmeghachi omume kemịkalụ na-eme n'oge usoro nchacha nke mbụ bụ ndị a:

Si+2NaOH+H2O=Na2SiO3+2H2↑

2) Alkali ederede

Ebumnobi: Iji mee anisotropic corrosion nke kristal na silicon elu site lye na-etolite pyramid na elu size nke 5um, na pyramid suede elu nwere ọmarịcha ìhè ọnyà na mgbochi echiche mmetụta (10%). Ederede Alkali na-eji ngwọta NaOH na mgbakwunye ederede.

Tinye ego kwesịrị ekwesị nke ngwọta NaOH na ntinye ederede (NaOH ngwọta ntinye ihe dị ka 0.6%, ntinye ntinye ederede nke ihe dị ka 0.4%) na tank alkali, nke nwere ike belata esemokwu elu nke silicon wafers, meziwanye mmetụta wetting nke silicon wafers. na mmiri NaOH, na-akwalite ntọhapụ nke hydrogen afụ, na-eme ka anisotropy nke corrosion dịkwuo elu, mee ka pyramid ahụ dịkwuo mma ma na-agbanwe agbanwe, na-eme ka mmepụta mmepụta nke suede elu. Usoro mmeghachi omume kemịkalụ nke guzobe suede bụ nke a:

Si+2NaOH+H2O=Na2SiO3+2H2↑

Na-arụ ọrụ okpomọkụ nke alkali texturing tank bụ 82 Celsius C, na akara oge nke alkali texturing bụ 420s.

3) Sachaa ma emechaa

The silicon wafer mgbe alkali texturing na-abanye na post-ehicha tank iji wepụ ihe fọdụrụ organic okwu na hụ na ịdị ọcha nke silicon wafer elu, si otú ahụ na-emeziwanye batrị ntughari arụmọrụ ruo n'ókè ụfọdụ. Mgbe imikpu n'ime wafer silicon a na-ebu ibu, hichaa ya, tinye mmiri dị ọcha na tank ahụ, ma gbakwunye ihe ngwọta NaOH kwesịrị ekwesị ma ọ bụ ngwọta nhicha (A na-atụ anya na ntinye uche NaOH ga-abụ 0.6%, a na-atụ anya na ntinye H2O2 ga-abụ 1.5%) dị ka. Oke maka nhicha dị elu (60 Celsius C). Mgbe ihichachara, a na-eme mmiri dị ọcha. Nhicha mmiri dị ọcha bụ ihicha imi mmiri na-erubiga ókè, a na-eme ya na ụlọ okpomọkụ.

4) Ịkọwa

Mgbe emechara nhichapụ, a na-achọ ihe ngwọta acid dilute (3.15% HCl na 7.1% HF) maka nhicha dị ọcha, ọrụ HCl bụ iji kpochapụ ihe fọdụrụ NaOH, ọrụ HF bụ iwepu oyi akwa oxide n'elu. na silicon wafer na-eme ka elu nke silicon wafer ọzọ hydrophobic, na-akpụ a mgbagwoju nke silicon H2SiF6, site na mgbagwoju na metal ions ikewapụ metal ion si n'elu nke silicon wafer, nke mere na metal ion ọdịnaya nke silicon wafer. belatara, na nkwadebe maka mgbasa na nkwụsị. A na-eme nhicha mmiri dị ọcha mgbe pickling gasịrị.

Mmeghachi omume kemịkalụ na-eme n'oge usoro pickling bụ ndị a:

HCl + NaOH = NaCl + H2O

SiO2+6HF=H2SiF6+2H2O

Ọnọdụ okpomọkụ na-arụ ọrụ nke tankị pickling bụ okpomọkụ nkịtị, na oge nchịkọta njikwa bụ 120s.

5) Na-ebuli ngwa ngwa tupu akpịrị ịkpọ nkụ

Nzube: Tupu-ekpochapụ elu nke silicon wafers kristal, na-emekarị dị ka nzọụkwụ ikpeazụ na usoro nhicha mmiri dị ọcha.

A na-ebufe wafer silicon kristal kristal na mmiri dị ọcha na-ebufe na oghere na-adọkpụ ngwa ngwa, a na-ebufe silicon wafer ahụ n'ime mmiri dị ọcha ka a na-emikpu ya kpamkpam, wee jiri nwayọọ nwayọọ bulie elu site na onye na-emegharị ihe na nkata nghọta, na esemokwu elu nwere ike ịdaba. ihe nkiri mmiri na silicon wafer.

Ọkpụkpụ a na-adọta ngwa ngwa na-agụnye tankị nhicha na usoro ịdọrọ ngwa ngwa, nke na-emechi ọkara. Enwere ọdụ ụgbọ mmiri serrated n'ime tankị nhicha, na mmiri dị ọcha na-aga n'ihu na-asachapụ nsị nke ebe a na-ehicha ihe n'oge a na-arụ ọrụ, na-eme ka mmiri dị mma nke tankị dị ọcha, ka o wee nweta mmetụta nhicha; Mgbe a na-edobe mmiri ahụ ọcha, ọ dịghị ntụpọ mmiri ga-apụta n'elu ebe a na-arụ ọrụ n'okpuru ọrụ nke ịdọrọ nwayọọ nwayọọ, ọ gaghị enwekwa akara mmiri mgbe ihicha.

6) Tumble akọrọ

A na-ebufe wafer silicon kristal na tankị ihicha, na ikuku na-ekpo ọkụ na 90 Celsius na-agbapụ na ala silicon wafer maka ihicha, na ihicha na-ekpo ọkụ eletrik.

Na usoro ederede dị n'elu, usoro nhichapụ na alkali texturing ga-emepụta mmiri mkpofu alkaline dị elu nke nwere sodium hydroxide (W1, W3, W5) na alkaline ihicha mmiri mkpofu (W2, W4, W6), na usoro pickling ga-emepụta. mmiri mkpofu acidic dị elu (W7) nwere hydrochloric acid na hydrofluoric acid na mmiri mkpofu acidic n'ozuzu (W8, W9). A na-arụ ọrụ a dị n'elu na igwe texturing mechiri emechi, usoro pickling ga-eme ka gas mkpofu acid (G1) nwere HF na HCl, nke a na-anakọta site na pipeline ma zigara ya na gas na-ekpofu gas maka ọgwụgwọ.

Mgbasa boron

Ebumnuche nke usoro mgbasa ozi bụ ịmepụta njikọ PN na silicon wafer iji ghọta ngbanwe nke ike ọkụ na ike eletrik. Ngwa nrụpụta PN junction bụ ọkụ na-ekesa, ọrụ ahụ na-eji boron trichloride gaseous iji gbasaa silicon wafer n'ime ọkụ mgbasa, na atom boron na-abanye na silicon wafer site na mgbasa, ma n'otu oge ahụ na-etolite akwa iko borosilicate n'elu. nke silicon wafer. Usoro mmeghachi omume bụ isi bụ:

4BCl3+3O2→2B2O3+6Cl2↑

2B2O3+3Si→3SiO2+4B

Ọkụ mgbasa ozi bụ akụrụngwa nrụgide na-adịghị mma mechiri emechi, nke nwere ntinye ikuku na ntinye ikuku, na-eji ọkụ eletrik, ngwa ahụ na-abịa na mgbapụta igwe na-ekpo ọkụ na-enweghị mmanụ. Usoro a kapịrị ọnụ bụ: buru ụzọ gafere nnukwu mmiri nke N2 iji chụpụ ikuku n'ime ọkụ ọkụ quartz tube, wee kpoo ọkụ ọkụ na-agbasa, chere ka ọkụ ọkụ na-ebili ruo 1050 Celsius C na mgbe niile, tinye wafer n'ime ite. ụgbọ mmiri quartz, ziga ya na ọnụ ọkụ ọkụ maka ikpo ọkụ maka nkeji iri abụọ, wee banye n'ime mpaghara okpomọkụ mgbe niile, buru ụzọ webata oxygen, wee webata boron trichloride maka mgbasa, oge usoro oge niile bụ nkeji 20. N'oge mmeghachi omume ahụ, ma Si na O180 dị oke, BCl2 na-emeghachi omume kpamkpam, na C3 mepụtara na mmeghachi omume ahụ. Mgbe emechara mmeghachi omume ahụ, a na-eji ngwá ọrụ mkpofu N12 eme ihe na-ewepụ ihe ahụ na-akpaghị aka.

Nyocha nke njikọ mmepụta mmetọ: Isi njikọ mmetọ nke usoro a bụ njikọ mgbasa ozi mgbe mmeghachi omume na-emepụta chlorine (G2) jikọtara ya na oxygen fọdụrụnụ, nitrogen, wdg, nke a na-anakọta site na tube pụrụ iche, zigara gas gas na-ekpofu acid. scrubber maka ọgwụgwọ, anakọtara site na pipeline ma ziga ya na asacha gas na-ekpofu acid maka ọgwụgwọ.

HỤRỤ imegharị laser

Teknụzụ doping laser bụ doping dị arọ nke ọnụ ụzọ igwe (electrode) na kọntaktị na wafer silicon, ebe a na-edobe doping ọkụ (doping dị ala) na mpụga electrode. Site na mgbasa ọkụ, a na-ebu ụzọ gbasaa n'elu nke silicon wafer na-emepụta doping ìhè; N'otu oge ahụ, a na-eji BSG elu (iko borosilicate) dị ka isi iyi redoping laser mpaghara, na site na mmetụta ọkụ mpaghara nke laser ahụ, atom ndị dị na BSG na-agbasa ngwa ngwa n'ime wafer silicon nke ugboro abụọ, na-eme mgbanwe mpaghara. mpaghara.

Usoro laser nke SE na-emepụta gas iyuzucha uzuzu (G3), nke igwe igwe na-anakọta uzuzu nke onwe ya na-ewepụ ya site na usoro ikpochapu elu ụlọ nke ụlọ ọrụ ahụ (ịdị elu ihe dị ka mita 15).

Post-oxidation

Ebe a na-agwọta elu nke silicon wafer site na laser SE, a na-ebibi oxide oyi akwa na boron mgbasa n'elu (n'ime kenkowaputa elu) site na ntụpọ ike laser. Mgbe alkali polishing etching, a na-achọrọ oyi akwa oxide dị ka oyi akwa mkpuchi iji chebe elu mgbasa ozi site na (n'ime elu na-egbuke egbuke) nke silicon wafer. Ya mere, a chọrọ nrụzi oxide nke elu nke laser SE nyochara.

N'ime ọrụ a, a kwadebere oyi akwa SiO2 oxide site na ikuku oxygen oxidation thermal. A na-eme usoro oxidation dum n'ime ọkụ oxidation, nke bụ ngwá ọrụ nrụgide ikuku mechiri emechi na ọkụ eletrik na-ekpo ọkụ. Nke mbụ, a na-eji mpempe akwụkwọ akpaka na-ebufe silicon wafer na ụgbọ mmiri quartz, mgbe ahụ, onye na-arụ ọrụ akpaka na-etinye ụgbọ mmiri quartz na silicon carbide cantilever slurry of the oxidation oven, na silicon carbide paste na-eziga quartz ụgbọ mmiri nke silicon. na-abanye n'ime tube ọkụ quartz dị elu. Mgbe ụgbọ mmiri quartz na-abanye n'ime ọkụ ọkụ, a na-emechi ọnụ ụzọ ọkụ ahụ, a na-amalite mmemme oxidation, na ọkụ oxidation na-agba ọsọ na-akpaghị aka. Mmeghachi omume kemịkalụ bụ isi na-eme n'oge oxidation thermal bụ:

Si+O2=SiO2

O2 na-emeghachi omume na elu nke silicon wafer na elu okpomọkụ na-etolite SiO2, na a ụfọdụ ego nke nitrogen ewebata ịnọgide na-enwe nrụgide mgbe nile na ọkụ tube. Nọgide na-enwe oge nke elu okpomọkụ oxygenation, nke mere na a ụfọdụ ọkpụrụkpụ nke SiO2 mkpa oyi akwa na-guzobere n'elu nke silicon wafer, na usoro parameters bụ: oxidation okpomọkụ 750 °C, nitrogen eruba ọnụego 12L / min, oxygen eruba ọnụego 5L. /min, 25min oge oxidation. Usoro a na-emepụta ikuku ikuku oxidized (ikuku ọkụ) nke nwere oxygen na nitrogen, bụ nke a na-esi na ọdụ ụgbọ mmiri nke ọkụ oxidation na-esi na ya pụta site na usoro ikpo ọkụ nke ụlọ nke ụlọ ọrụ ahụ.

Ịgba ọkụ

1) Gaa na BSG

A na-ewepụ silicon wafer site na-ese n'elu mmiri na a yinye Cleaner (azụ kọntaktị na acid), akụkụ bụ isi nke acid bụ 24.5% HF, na isi mmeghachi omume mmeghachi omume kemịkal gụnyere:

HF+SiO2→SiF4+H2O

SiF4+HF→H2SiF6

A na-asacha ya na mmiri wee kpoo ya site na mma ikuku tupu ịbanye na usoro ọzọ. Ngwá ọrụ nke igwe nhicha BSG bụ ihe eji eme ihe na-emechi emechi, nke na-ejikọta tank tank na mmiri dị ọcha, ma kwadebere ya na usoro mmepụta ihe na-eme ka ọ bụrụ ebe nrụgide micro-negative na ngwá ọrụ na-anakọta gas na-agbanwe agbanwe.

Isi mmetọ dị na njikọ a gụnyere gas iyuzucha acid (G4) nke nwere HF, nke a na-anakọta site na pipeline ma zigara ya na ndị na-ekpochapụ gas gas maka ọgwụgwọ. na mmiri mkpofu acid gbadoro anya nke ukwuu nwere hydrofluoric acid (W10) na mmiri mkpofu acid izugbe (W11).

2) Etching azụ

Iji mee ka ngosipụta nke azụ nke silicon wafer dịkwuo mma, a na-ehichapụ azụ nke silicon wafer site na alkali na onye na-egbuke egbuke.

Ngalaba polishing alkali (ahịrị 6) na-agụnye tupu ịsacha-mmiri-mmiri alkali polishing * 2-hydrogen peroxide ihicha (echekwara) -micro-texturing (echekwabara) -mmiri dị ọcha ihicha-mkpochapụ-ihicha-mmiri dị ọcha-pickling * 2 -ịsacha mmiri dị ọcha mgbe ebuli ngwa ngwa na-ebuli elu, tupu akpọnwụ akpọnwụ akpọnwụ *5 na modul ndị ọzọ. A na-eme usoro ọrụ niile nke azụ etching na-akpaghị aka, iji ogwe aka na-ebufe iji zipu silicon wafer a kpochara nke ọma na ebe nri nke igwe na-atụba alkali, silicon wafer na akpaka mechiri emechi alkali na-atụba igwe site na roller site na nke ọ bụla. corrosion, tankị nhicha, akụrụngwa njikwa akpaaka iji gbakwunye acid, lye na mmiri dị ọcha na modul nke ọ bụla, a na-agbanye acid na lye n'ime tank site na pipeline, a na-ewepụkwa mmiri mkpofu na tank ahụ mgbe niile.

3) Tupu ihicha

Mgbe nhazichara, wafer silicon na-abanye n'ime tankị nhicha iji wepụ ihe ndị fọdụrụ na ya ma hụ na ịdị ọcha nke silicon wafer dị n'elu, si otú ahụ na-eme ka ntụgharị cell dịkwuo mma ruo n'ókè ụfọdụ. A na-emikpu wafer silicon a na-ebu ibu n'ime mmiri dị ọcha, a na-agbakwunye mmiri dị ọcha na tank ahụ, na ego kwesịrị ekwesị nke ngwọta NaOH ma ọ bụ ngwọta nhicha (a na-atụ anya na ntinye NaOH ga-abụ 0.39%, H2O2 na-atụ anya na 0.61%) gbakwunyere. dị ka oke maka ikpocha ọkụ dị elu (60 Celsius C). Nhicha mmiri dị ọcha mgbe emechara ya. Nhicha mmiri dị ọcha bụ ihicha imi mmiri na-ejubiga ókè, a na-eme ya na ụlọ okpomọkụ maka 100s.

4) alkali ịtụba

A na-eji mmiri dị ọcha mee ihe nke alkali na-atụba mmiri, a na-agbakwunyekwa ihe ngwọta NaOH kwesịrị ekwesị na ihe mgbakwunye na-egbuke egbuke (ihe dịka 1.6% nke ngwọta NaOH, 0.97% nke onye na-emepụta ihe na-egbuke egbuke), mgbe ahụ, a na-egbukepụ azụ azụ nke silicon wafer. okpomọkụ na-arụ ọrụ nke 65 Celsius. A na-esochi ịtụba alkali na-ehicha mmiri dị ọcha. Mmeghachi omume kemịkalụ na-eme n'oge usoro ịtụba alkali bụ ndị a:

Si+2NaOH+H2O=Na2SiO3+2H2↑

Na-arụ ọrụ okpomọkụ nke alkali na-atụba tank bụ 65 Celsius C, na njikwa alkali ịtụ oge bụ 220s.

5) Post- Cleaning na micro-textureing

A na-agbakwunye mmiri dị ọcha na tank ahụ, na ego kwesịrị ekwesị nke ngwọta NaOH na hydrogen peroxide (ihe dị ka 0.55% nke ngwọta NaOH, 0.25% nke hydrogen peroxide ntinye) ka agbakwunyere dịka nha maka ikpocha ụlọ okpomọkụ. Mgbe ihichachara, a na-eme nhicha mmiri dị ọcha.

Mmeghachi omume kemịkalụ na-eme n'oge usoro micro-texture bụ ndị a:

Si+2NaOH+H2O=Na2SiO3+2H2↑

6) Ịkọwa

Mgbe ihichachara, a na-achọ ihe ngwọta acid (0.9% HCl na 0.23% HF) maka nhicha dị ọcha, ọrụ HCl bụ iji kpochapụ ihe fọdụrụ NaOH, ọrụ HF bụ iwepụ oyi akwa oxide n'elu silicon. wafer iji mee ka elu nke silicon wafer dịkwuo hydrophobic, na-eme mgbagwoju anya nke silicon H2SiF6, site na mgbagwoju anya na ions ígwè iji kewaa ions ígwè site na elu nke silicon wafer, nke mere na ion ion ọdịnaya nke silicon wafer na-ebelata. , na nkwadebe maka mgbasa na nkwụsị. A na-eme nhicha mmiri dị ọcha mgbe pickling gasịrị.

Mmeghachi omume kemịkalụ na-eme n'oge usoro pickling bụ ndị a:

HCl + NaOH = NaCl + H2O

SiO2+6HF=H2SiF6+2H2O

Ọnọdụ okpomọkụ na-arụ ọrụ nke tankị pickling bụ okpomọkụ nkịtị, na oge nchịkọta njikwa bụ 100s.

7) Tumble akọrọ

A na-ebufe ngwa ngwa silicon wafer kristal na-ekpo ọkụ na-ebufe ya na tankị ihicha, a na-efesa silicon wafer na ikuku ọkụ na 90 Celsius C maka ihicha, na ihicha na-anabata ọkụ eletrik.

Na n'elu azụ etching usoro, na tupu ihicha, alkali na-atụba na post-nhicha Filiks ga-emepụta elu-concentration alkaline mkpofu mmiri nwere sodium hydroxide (W12, W14, W16) na izugbe alkaline ihicha mmiri mkpofu (W13, W15, W17), na usoro pickling ga-emepụta mmiri mkpofu acidic nwere nnukwu uche (W18) nwere hydrochloric acid na hydrofluoric acid na mmiri mkpofu acidic n'ozuzu (W19, W20). A na-arụ ọrụ a dị n'elu na ihe mkpuchi alkali mechiri emechi, na usoro nchịkọta ga-eme ka gas mkpofu acid (G5) nwere HCl na HF, nke a na-anakọta site na pipeline ma zigara ya na gas na-ekpofu gas maka ọgwụgwọ.

A na-etinye nkwụnye ego POPAID na ọnọdụ

Usoro POPAID bụ usoro dị mkpa maka mkpuchi efere a kwadebere site na ijikọ oyi akwa oxide tunneling na oyi akwa silicon kristal doped.

Nke mbụ, silicon wafer na-abanye n'ime oghere na-ebunye na gburugburu ikuku, na-ebufe n'ime ụlọ preheating 300 °, wee banye na oghere usoro PO, nke a na-ebuga O2 na ngọngọ nkesa gas site na trachea, na ionization na-arụ ọrụ site na ya. ike RF RF n'ime ion, na ions oxidize n'elu nke silicon wafer na-etolite a tunneling oxide oyi akwa; Mgbe ahụ, silicon wafer na-agafe na ntughari na oghere nchekwa ma na-ebuga ya n'ime oghere a na-akwụ ụgwọ, na isi iyi a na-akwụ ụgwọ na-etinye ụfọdụ ọkpụrụkpụ nke silicon amorphous n'azụ nke mkpụrụ ahụ, n'otu oge ahụ, a na-ewebata gas PH3 n'oge ntinye ego. usoro, na phosphorane gas na-abanye n'ime igwe. Site na 10kev na 0.5-2kev elu-voltage redio ugboro iji kpalie phosphorus na phosphorus n'ime steeti ion phosphorus, a na-agbakwunye voltaji dị elu DC n'etiti isi iyi ion na ala, nke mere na ion phosphorus na-enweta ume site na elu- voltaji eletriki ubi, obosara nke doo bụ 420mm, na mgbe ahụ silicon wafer na-ebunye n'okpuru doo, na atom nke ugwo isi iyi na-ebu P ion ma ọ bụ meghachi omume na P ion n'oge ụgbọ elu na mkpụrụ iji nweta na situ phosphorus doping. .

Usoro mmeghachi omume bụ isi bụ: PO+PAID=POPAID

Plasma oxidation (PO): SiH4 + O2 → SiO2

Plasma-enyere aka na doping doping (PAID): Si (isi iyi) + PH3→n-Si

Mgbe emechara mmeghachi omume ahụ, a na-ekpocha ya na nitrogen, na ntinye ion na-abịa na adsorbent, ọgwụgwọ ọgwụgwọ nwere ike iru 100%, ntinye phosphorane tupu ịbanye n'ụlọ elu adsorption bụ 179.05ppm, na PH3 ahụghị mgbe adsorption gasịrị. Ihe oru ngo a bu n'obi ijikọ gas na-ekpocha ọkụ a na ụlọ elu gas gas DA003 maka ọgwụgwọ na igbapu, na ụlọ ọrụ ahụ na-ezube ịwụnye mkpuchi akpaaka maka nkwụsị nke phosphorane, na njedebe nchọpụta nke 0.1mg / m3.

Nyocha nke njikọ mmepụta mmetọ: Isi njikọ mmetọ nke usoro a bụ Ar, PH3 na N2 ewepụtara n'oge usoro a, nke a na-anakọta site na ọkpọkọ pụrụ iche ma zigara ya na gas scrubber n'efu acid maka ọgwụgwọ.

nkwụsị

A na-etinye wafer silicon na tube mmeghachi omume nke iko quartz, na tube mmeghachi omume na-ekpo ọkụ na ọkụ ọkụ ọkụ ọkụ waya na-ekpo ọkụ na ụfọdụ okpomọkụ (okpomọkụ a na-ejikarị bụ 900 ~ 1200 Celsius C, nke nwere ike belata ruo n'okpuru 600 Celsius). C n'okpuru ọnọdụ pụrụ iche), na mgbe oxygen na-agafe na tube mmeghachi omume, mmeghachi omume kemịkalụ na-eme n'elu nke silicon wafer:

Si (siri ike) + O2 (gaseous) → SiO2 (siri ike)

Mweghachi nke adịghị ọcha na-emepụta site na usoro nkwụsịtụ na-ekerekwa òkè na ntinye adịghị ọcha, na mgbasa ozi na nhazi nke sodium na potassium ion nke PSG na-eji wepụ ion ndị a na-emerụ ahụ.

Nyocha njikọ mmepụta mmetọ: Isi njikọ mmetọ nke usoro a bụ ikuku oxygen na nitrogen fọdụrụ na njikọ ikuku oxygen.

BOE nhicha

BOE (5-line) trough akụrụngwa bụ ihe ejikọtara ọkara mechiri emechi, a na-etinyekwa wafer silicon na nkata site na akụrụngwa akpaaka wee gbanwee na ngwọta tank ọ bụla na akụrụngwa site na ogwe aka robotic. N'ime ha, tankị kemịkalụ na-ejupụta mgbe niile na kemịkalụ kwekọrọ na ntinye nke ngwọta ahụ, a na-edochikwa ya dum mgbe niile. A na-awụpụ mmiri mkpofu a dochie anya n'ime usoro mmiri mkpofu na n'ikpeazụ n'ime ebe a na-edozi nsị maka ọgwụgwọ. A na-eji mmiri dị ọcha na-ehicha tankị mmiri na-asacha, mgbe e nwere silicon wafers na sink, a na-eji nwayọọ nwayọọ na-agbakwunye mmiri dị ọcha, mmiri saline na-asọba na-akpaghị aka na usoro nchịkọta mmiri na-ekpofu mmiri, n'ikpeazụkwa na-abanye n'ọdụ ụgbọ mmiri maka ọgwụgwọ. Kemịkalụ niile bụ mmiri mmiri ma na-ebusa ya ozugbo site na nfuli diaphragm. Usoro ihicha bụ: pickling tank * 2, mmiri ịsacha, post-pickling (HCL / HF / DI), mmiri ịsacha, ngwa ngwa ebuli, ihicha * 6, tank size 720L.

1) Ịkọwa

Ọ dị mkpa iji ngwọta acid dilute (3.15% HCl na 7.1% HF) maka nhicha dị ọcha, ọrụ nke HCl bụ iji ion ígwè Cl- complexed, ọrụ HF bụ iwepụ oyi akwa oxide n'elu. na silicon wafer na-eme ka elu nke silicon wafer ọzọ hydrophobic, na-akpụ a mgbagwoju nke silicon H2SiF6, site na mgbagwoju na metal ions ikewapụ metal ion si n'elu nke silicon wafer, nke mere na metal ion ọdịnaya nke silicon wafer. belatara, HF pickling 150s iji wepụ BSG n'ihu na oyi akwa PSG n'azụ, a na-eme nhicha mmiri dị ọcha mgbe ịchachara.

HF+SiO2→SiF4+H2O

SiF4+HF→H2SiF6

2) pickling mgbe pickling

Mgbe emechara nhichapụ, ọ dị mkpa iji ngwọta acid dilute (14.7% HF) maka nhicha dị ọcha dị elu, ọrụ HF bụ iwepụ oxide oyi akwa n'elu nke silicon wafer iji mee ka elu nke silicon wafer dịkwuo elu. hydrophobic, na-eme mgbagwoju anya nke silicon H2SiF6, ma wepụ ions ígwè si n'elu nke silicon wafer site na mgbagwoju anya na ion metal, nke mere na ion ion ọdịnaya nke silicon wafer na-ebelata.

Mmeghachi omume kemịkalụ na-eme n'oge usoro nchịkọta bụ ndị a: SiO2+6HF=H2SiF6+2H2O

Ọnọdụ okpomọkụ na-arụ ọrụ nke tankị pickling bụ okpomọkụ nkịtị, na oge nchịkọta njikwa bụ 100s.

3) Tumble ihicha

A na-ebufe ngwa ngwa silicon wafer kristal na-ekpo ọkụ na-ebufe ya na tankị ihicha, a na-efesa silicon wafer na ikuku ọkụ na 90 Celsius C maka ihicha, na ihicha na-anabata ọkụ eletrik.

Usoro nchịkọta nke dị n'elu ga-emepụta mmiri mkpofu acidic nwere HCl, hydrofluoric acid (W21) na mmiri mkpofu acidic nwere nnukwu acid nke nwere hydrofluoric acid (W23), na mmiri mkpocha acid zuru oke (W22, 24, 25). A na-arụ ọrụ a dị n'elu na igwe nhicha mechiri emechi, usoro pickling ga-agbanwe gas iyuzucha gas (G6) nke nwere HCl na HF na gas gas gas nke nwere HF (G7), nke a na-anakọta site na pipeline ma zigara ya na ndị na-ehichapụ gas gas. maka ọgwụgwọ.

BỤ

A na-eji ngwa ALD kpuchie elu nke silicon wafer na akwa Al2O3 iji melite ngafe na mmetụta nnabata adịghị ọcha na elu nke wafer silicon. Ọ na-ejikarị Al (CH3) 3 gaseous meghachi omume na mmiri vapor (H2O) iji mepụta Al (OH) 3, nke na-ejikọta n'elu silicon wafers ma na-emepụta gas methane.

Usoro mmeghachi omume bụ isi bụ:

Al(CH3)3+3H2O→Al(OH)3+3CH4↑

2Al(OH)3→Al2O3+3H2O↑

ALD akụrụngwa bụ mechiri emechi adịghị mma nrụgide akụrụngwa, onwem na ikuku mbata, ntinye, ntinye na ntinye, kpo oku bụ electric kpo oku, ngwá na-abịa na mmanụ-free akọrọ igwe agụụ mgbapụta. Mgbe mmalite nke mmepụta, ogwe aka robot na-ebu ụzọ zụọ mkpụrụ ndụ n'ime ngwa ALD ma mechie oghere ihe. Kpoo ọkụ na okpomọkụ ụfọdụ, oghere iji mee ka nrụgide dị na akụrụngwa na-egbo mkpa mmepụta. A na-emepụta ihe nkiri ahụ edobere AL2O3 site na ntụgharị mgbanwe nke gas-phase precursor TMA na H2O n'ime ụlọ mmeghachi omume ma tinye kemịkal na matriks nkwụnye ego. N'ikpeazụ, mgbe dochie methane iyuzucha gas na akụrụngwa site nitrogen, gbanye akụrụngwa na-akpaghị aka wepụ silicon wafer.

Isi ihe na-emerụ emerụ na njikọ a bụ methane gas iyuzucha (G8), nke a na-ebupụ site na mgbapụta agụụ ma na-agwọ ya site na igwe anaghị agba nchara silane combustion cylinder + mmiri na-agba mmiri.

Mkpuchi ihu

Ụkpụrụ bụ isi bụ iji photodischarge dị elu na-emepụta plasma iji metụta usoro ntinye ihe nkiri dị mkpa, na-akwalite mwepu, kemịkalụ, mkpali na ionization nke ụmụ irighiri gas, na ịkwalite nguzobe nke ndị na-emegharị ihe. Ebe ọ bụ na ọnụnọ NH3 na-enye aka na mgbasa na mgbasa nke ìgwè ndị na-arụ ọrụ, a na-eme ka ọganihu nke ihe nkiri ahụ dịkwuo mma, a na-ebelata okpomọkụ nke nkwụnye ego.

Mmeghachi omume kemịkalụ bụ isi na-eme n'oge ntinye ihe nkiri silicon oxide site na PECVD bụ:

SiH4+NH3+N2O→xSi2O2N4+N2↑+yH2↑

Ngwa ihe nkiri dị mma nke PECVD bụ akụrụngwa nrụgide na-adịghị mma mechiri emechi, kpo oku eletrik, yana mgbapụta igwe na-ekpo ọkụ na-enweghị mmanụ. N'oge mmepụta, buru ụzọ jupụta akụrụngwa na nitrogen, ogwe aka nke robotic na-emecha ụgbọ mmiri na-ebufe silicon wafer, mgbe nrụgide mpụga dị na ngwa ahụ rutere n'ọdụ ụgbọ mmiri, mepee ọdụ ụgbọ mmiri na ọdụ ụgbọ mmiri, ụgbọ mmiri graphite na-abanye ngwa ngwa, ma mechie ntinye ahụ. na ntinye. Ịchacha na ime nyocha nchekwa dị iche iche, mgbe ị kwadoro nchekwa, a na-ebute silane na amonia iji mechaa mkpuchi silicon oxide na akụrụngwa. Mgbe emechara mkpuchi ahụ, a na-ahapụ gas fọdụrụnụ na pipeline gas pụrụ iche na akụrụngwa site na nitrogen, mgbe ahụ, a na-emeghe ntinye na ntinye ma wepụ ihe ahụ. Mgbe ọ dị jụụ, ọ na-abanye na njedebe ma na-abanye na usoro na-esote.

Nyocha nke njikọ mmepụta mmetọ: Ụdị mmetọ bụ isi nke usoro mmepụta bụ mkpuchi gas efu (silane, gas na-achị ọchị, oke amonia, hydrogen, nitrogen, wdg) (G9), nke mbụ na-abanye na cylinder silane combustion cylinder site na igwe anaghị agba nchara. kpaliri usoro ikuku, wee wepụ ya mgbe ọgwụgwọ gasịrị site na ụlọ elu ịgba.

Mkpuchi na azụ

Mmeghachi omume kemịkalụ bụ isi na-eme n'oge ntinye ihe nkiri silicon oxide site na PECVD bụ:

SiH4+NH3+N2O→xSi2O2N4+N2↑+yH2↑

A na-emechi ngwa ihe nkiri na-akwado PECVD akụrụngwa nrụgide na-adịghị mma, kpo oku eletrik, yana mgbapụta igwe na-ekpo ọkụ na-enweghị mmanụ. N'oge mmepụta, buru ụzọ jupụta akụrụngwa na nitrogen, ogwe aka nke robotic na-emecha ụgbọ mmiri na-ebufe silicon wafer, mgbe nrụgide mpụga dị na ngwa ahụ rutere n'ọdụ ụgbọ mmiri, mepee ọdụ ụgbọ mmiri na ọdụ ụgbọ mmiri, ụgbọ mmiri graphite na-abanye ngwa ngwa, ma mechie ntinye ahụ. na ntinye. Ịchacha na ime nyocha nchekwa dị iche iche, mgbe ị kwadoro nchekwa, a na-ebute silane na amonia iji mechaa mkpuchi silicon oxide na akụrụngwa. Mgbe emechara ihe mkpuchi ahụ, a na-ahapụ gas fọdụrụnụ na pipeline gas pụrụ iche na akụrụngwa site na nitrogen, mgbe ahụ, a na-emeghe ntinye na ntinye ma wepụ ihe ahụ. Mgbe ọ dị jụụ, ọ na-abanye na njedebe ma na-abanye na usoro na-esote.

Nyocha nke njikọ mmepụta mmetọ: Ụdị mmetọ bụ isi nke usoro mmepụta bụ mkpuchi gas efu (silane, gas na-achị ọchị, oke amonia, hydrogen, nitrogen, wdg) (G9), nke mbụ na-abanye na cylinder silane combustion cylinder site na igwe anaghị agba nchara. kpaliri usoro ikuku, wee wepụ ya mgbe ọgwụgwọ gasịrị site na ụlọ elu ịgba.

Metallization

1) Mbipụta

N'oge a na-ebipụta usoro, slurry dị n'elu ihuenyo, na scraper na-pịa na ihuenyo efere na ụfọdụ nrụgide, nke mere na ihuenyo deformation kọntaktị n'elu nke silicon wafer. The slurry na-extruded na kọntaktị n'elu nke silicon wafer; Ike mgbasa ozi elu nke silicon wafer dị ukwuu, a na-apụkwa slurry na ntupu. N'oge a, scraper na-agba ọsọ, na mbụ ntupu efere bụ n'okpuru omume nke ọma mgbake ike, nke mere na slurry dara were were n'elu nke silicon wafer. N'ime ha, tapawa ọlaọcha bụ mpempe akwụkwọ mpempe akwụkwọ nke ọla ọcha dị oke mma na nke dị elu dị ọcha na ntụ ntụ aluminom dị ka ígwè bụ isi, yana ụfọdụ ihe nkedo organic na resin dị ka ndị na-enyere aka.

Mbụ niile, azụ electrode obibi na ihicha: n'ụzọ ziri ezi ọnọdụ na e biri ebi azụ electrode mado (gụnyere laser punching ọnọdụ) (ọlaọcha mado) na azụ nke batrị, na ngwa ngwa nkụ na obere okpomọkụ iji hụ na e biri ebi azụ electrode adịghị emebi emebi. mgbe ebi akwụkwọ na nzọụkwụ ọzọ.

Nke abuo, n'azụ n'akụkụ ezi okporo akara obibi, ihicha: na azụ nke batrị ka n'ụzọ ziri ezi ọnọdụ obibi akwụkwọ mma okporo akara mado (ọlaọcha mado), na ngwa ngwa ọkpọọ na ala okpomọkụ, isi nzube bụ ịkpọtụrụ na silicon matriks. nyefee ugbu a, na re-dope, belata nchikota nke ụgbọelu, na-abawanye nkwalite.

Mgbe ahụ gafere na flipper, na mpempe batrị tụgharịrị site na azụ gaa n'ihu elu. Ezi electrode obibi na ihicha: n'ụzọ ziri ezi na-edebe ndị e biri ebi nti electrode tapawa (ọlaọcha mado) na n'ihu batrị, na nkụ ngwa ngwa na ala okpomọkụ, isi ọrụ bụ na-eduzi na-ebufe ugbu a anakọtara site mkpa okporo akara na mpụga. sekit ma ọ bụ ebe nchekwa.

N'ikpeazụ, n'ihu n'akụkụ ezi okporo akara obibi, ihicha: na n'ihu batrị n'ụzọ ziri ezi ọnọdụ na mado (ọlaọcha mado) e biri ebi n'ihu electrode, mgbe obibi, na-eche ịbanye sintering ọkụ siri ike sintering, na-etolite a ọma ohmic kọntaktị, isi. Ọrụ bụ ịnakọta ugbu a, welie ikike nnabata ọkụ nke mpempe akwụkwọ batrị, melite arụmọrụ ntụgharị.

Okpomọkụ ihicha nke slurry na usoro ihicha dị n'elu bụ ihe dịka 200 Celsius. Usoro a na-emepụta gas na-agbanwe agbanwe (G10), na isi ihe na-emetọ ya bụ mmanya ester iri na abụọ, nke VOC tụrụ. A na-anakọta gas mkpofu ahịhịa sitere na usoro obibi akwụkwọ site na mkpuchi mkpuchi gas, na-anakọta ma na-agwọ ya site na igbe mgbasa ozi carbon nke abụọ na-arụ ọrụ nke abụọ, ma mesịa wepụta ya site na cylinder iyuzucha. Ọ dị mkpa ka a na-ehicha ya ma na-ehicha ya mgbe niile iji nọgide na-arụ ọrụ nke ọma.

2) Ịkọwa

Sintering bụ sinter isi ezi okporo mado e biri ebi na silicon wafer n'ime a batrị mpempe akwụkwọ na elu okpomọkụ, nke mere na electrode na-agbakwunyere na elu na-etolite a ike n'ibu kọntaktị na ezi njikọ eletriki, na n'ikpeazụ electrode na silicon. wafer n'onwe ya na-etolite kọntaktị ohmic.

A na-eji ọkụ ọkụ na-ekpo ọkụ na-ekpo ọkụ (ọkụ ọkụ eletrik), a na-ekewa ọkụ ọkụ na-ekpo ọkụ na mpaghara okpomọkụ dị iche iche, na-emepụta electrodes elu na nke dị ala n'oge usoro nsị, na okpomọkụ kachasị elu bụ 700 ~ 800 ° C. . Na usoro a, organic ihe mgbaze mmanya ester na slurry bụ kpamkpam volatilized na-etolite organic n'efu gas (G11), nke a na-atụ site VOCs, na mgbe ahụ ọkụ zuru ezu site na elu okpomọkụ combustion tower ngwaọrụ wee adsorbed site a 2-ogbo usoro na-arụ ọrụ carbon adsorption igbe na-ebi akwụkwọ n'efu gas, na hapụrụ site na iyuzucha cylinder mgbe adsorption.

3) Igwe ọkụ eletrik

Mgbe sel na-agbanyechara, a na-eji usoro ịgbanye ọkụ eletrik kpọmkwem nke ndị na-ebu ya (reverse injection of direct current) iji gbanwee ọnọdụ ebubo hydrogen na ahụ silicon, nke mere na ọ ga-eme ka mgbagwoju boron-oxygen na-ere ure, gbanwee ya n'ime ya. reecology kwụsiri ike, n'ikpeazụ wee nweta ebumnuche mgbochi fotodecay.

Nwalee nkwakọ ngwaahịa

Mgbe emechara cell cell, a na-anwale paramita arụmọrụ eletriki nke cell anyanwụ (dị ka ịlele ọnụọgụ IV ya na ọnụego ọkụ ọkụ, wdg) site na iji ngwa nyocha. Mgbe emechara ule ahụ, a ga-ekewa batrị na-akpaghị aka n'ọtụtụ gia dịka ụkpụrụ ụfọdụ siri dị. Mgbe ọnụọgụ mkpụrụ ndụ dị n'otu gia ruru ọnụọgụ akọwapụtara, akụrụngwa ahụ ga-echetara onye ọrụ ka ọ wepụta ya ma buru ya. Ngwaọrụ ahụ na-egosipụtakwa nchọpụta irighiri ihe, nke na-ajụ irighiri ihe mgbe achọtara ya, kama ịnwale ya dị ka batrị zuru oke, usoro na-emepụta cell mkpofu (S2).

【Disclaimer】 Ebumnuche nke ibipụta akụkọ a bụ ịnyekwu ozi ụlọ ọrụ, maka naanị ntụaka, ọ pụtaghị na ikpo okwu a na-ahụ maka echiche na ọdịnaya ya. Mmebi, biko kpọtụrụ Xiaobian ka ihichapụ, imekọ ihe ọnụ na ajụjụ ọ bụla, biko hapụ ozi n'azụ.